Press Release

January 18, 2023

January 18, 2023

Flexible Factory Partner Alliance

FFPA's Latest Technical Specifications Version 2.0 for Stable Operation of Various Wireless Systems in Factories are Now Publicly Available

- Added 5G control and multi-hop functions to provide optimal wireless communication for various use cases -

In response to growing expectations for wireless commutation at manufacturing sites, FFPA has released the latest SRF wireless platform communication standard, namely technical specifications version 2.0 to the public. In the technical specifications Ver.2.0, new functions such as 5G Control for Frequency Control, 5G Control for Multi-radio Integration Control, and Multi-hop Control have been added while maintaining backward compatibility with technical specifications Ver.1.1. The technical specifications define the reference architecture, functions, message parameters among functional blocks, typical sequence diagrams and data frames for the SRF wireless platform. They can be downloaded for free from the FFPA website (https://www.ffp-a.org/document/index.html.

[ Latest technical specifications Ver. 2.0 released to the public ]

Flexible Factory Partner Alliance (FFPA) has established communication standards of SRF (Smart Resource Flow) wireless platform, which is a coordinated control technology that stabilizes various and mixed wireless systems in manufacturing sites. In response to growing expectations for wireless use at manufacturing sites, FFPA has released the latest SRF wireless platform communication standard, namely technical specifications Ver. 2.0.

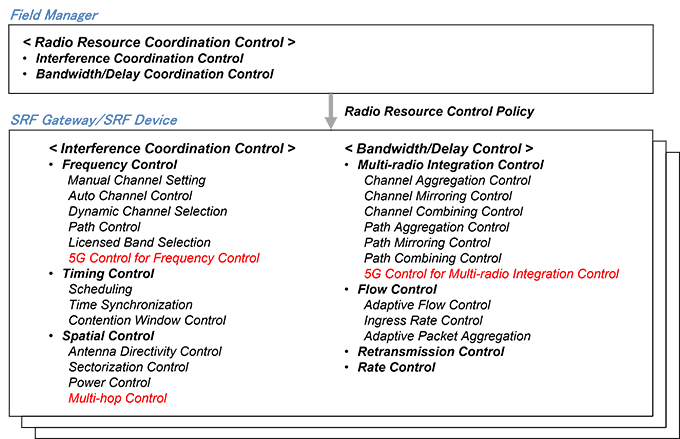

The technical specifications Ver.2.0 define the reference architecture, functions, messages and parameters among functional blocks, typical sequence diagrams, and data frames for the SRF wireless platform, and maintain backward compatibility with the technical specifications Ver.1.1, adding coordination control of the 5th generation mobile communication system (5G) and radio systems operating in unlicensed frequency bands, and expanding the network topology to enable multi-hop communication. Fig. 1 shows the function list (excerpts of functions related to radio resource control) defined in the technical specifications Ver.2.0. 5G Control for Frequency Control, 5G Control for Multi-radio Integration Control, and Multi-hop Control have been functions newly added to the technical specifications Ver.1.1. These functions are categorized into mandatory functions, which are basic controls, and optional functions, which are selected and implemented by the vendor to characterize their own devices or systems. Messages among functional blocks are defined by REST (Representational State Transfer) API (Application Programming Interface). Also, parameters are defined using JSON (Java Script Object Notation) format. The technical specifications Ver.2.0 can be downloaded for free from the FFPA website (https://www.ffp-a.org/document/index.html).

Fig. 1. List of functions defined in the technical specifications Ver.2.0 (excerpts of functions related to radio resource.)

[ Event ]

FFPA will exhibit at Smart Factory EXPO 2023, which will be held at Tokyo Big Sight (West 1F, West 2 Hall) from January 25th to 27th, 2023. FFPA and its member companies will present the latest technical specifications and topics related to the development of SRF wireless platform. For detail information, please contact the FFPA Secretariat (email::info@ffp-a.org).

[ Related information ]

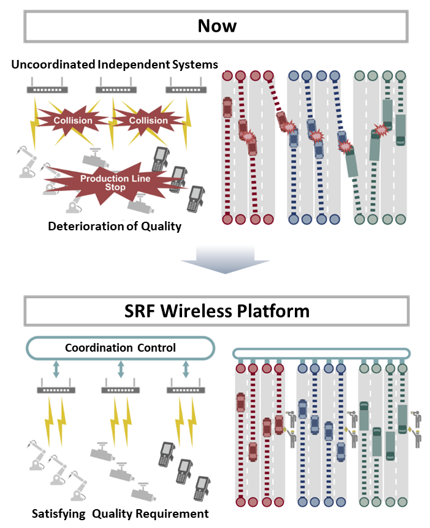

Challenges of wireless communication at the manufacturing sites

At manufacturing sites such as factories, it is expected to utilize more wireless technology, such as wireless communication within the factory that enables flexible changes in production lines to meet the diverse needs of consumers, and failure prediction of industrial machinery using wireless sensors [1]. On the other hand, instability of wireless communication has become an issue due to the mixture of various wireless systems in factories and the generation of radio noise from industrial machinery [1]. For example, in the unlicensed band used by wireless LAN, etc., multiple IoT devices are already being introduced at manufacturing sites, and if the radio waves emitted by such devices use the same frequency, they will interfere with each other and may cause communication failure, and thus, it may not be possible to maximize its potential [2].

FFPA tackled the issue by adopting the SRF wireless platform proposed by the National Institute of Information and Communications Technology (NICT) as the basic configuration of the system, and has developed communication standards to realize stable communication in an environment where multiple wireless systems coexist.

[1] White Paper 2020 on Information and Communications Japan, Ministry of Internal Affairs and Communications of Japan

https://www.soumu.go.jp/johotsusintokei/whitepaper/eng/WP2020/2020-index.html

[2] White Paper 2020 on Manufacturing, Ministry of Economy, Trade and Industry of Japan (in Japanese)

https://www.meti.go.jp/report/whitepaper/mono/2020/index.html

Configuration of SRF wireless platform

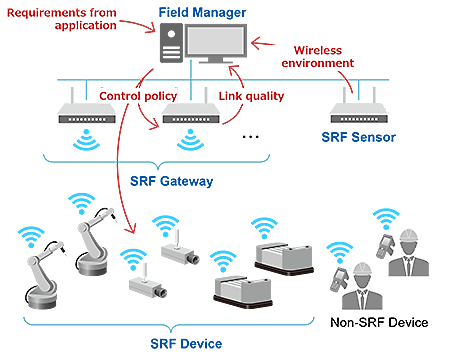

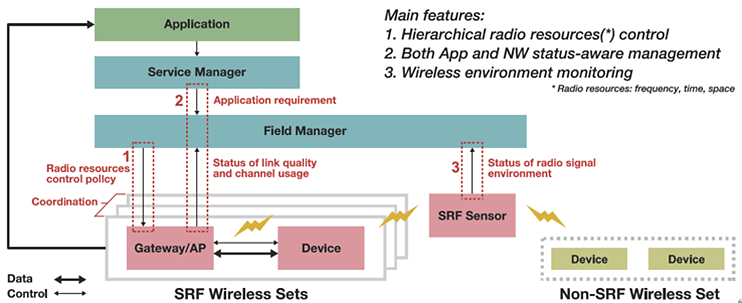

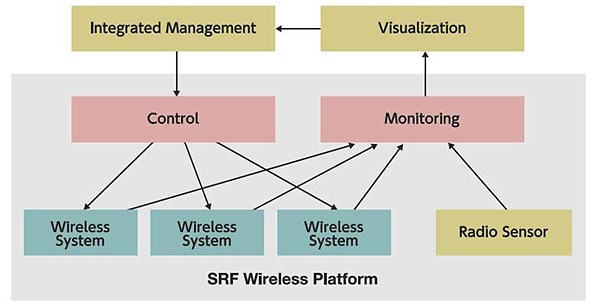

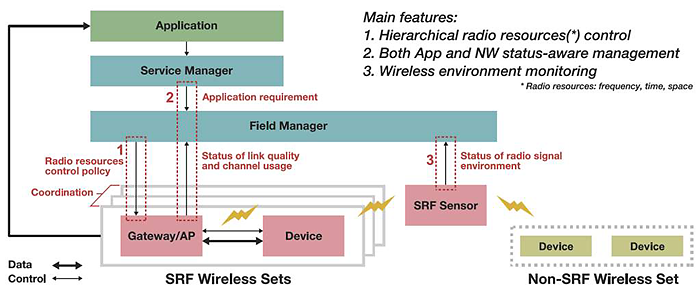

The SRF wireless platform consists of Field Manager, SRF Gateway, SRF Device, and SRF Sensor (Fig. 2). Field Manager is a controller that integrates and manages multiple wireless systems, coordinates wireless resources to meet application quality requirements to avoid radio wave interference, and allocates wireless resources to each wireless system according to control policies. SRF Gateway/SRF Device is a base/client unit that performs wireless communication under the control of Field Manager and notifies Field Manager of the measured wireless communication status. SRF Sensor is a wireless environmental sensor that detects and monitors wireless devices not under Field Manager control. These coordinated operations enable stable wireless communication in a wireless environment where multiple wireless systems coexist.

Fig. 2. Configuration of SRF wireless platform.

Overview of Technical Specifications Ver. 2.0 of SRF Wireless Platform

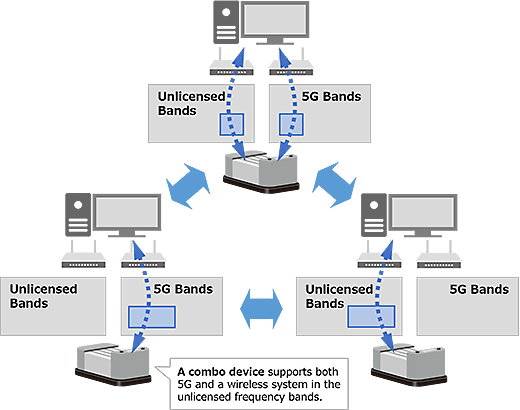

In the technical specifications Ver.2.0, in addition to wireless systems in unlicensed frequency bands that have been supported up to technical specifications Ver.1.1, 5G has been newly added as a wireless system to be appropriately controlled and it is integrally managed on the SRF wireless platform. By using the technical specifications Ver.2.0, wireless devices that support both 5G and unlicensed frequency band wireless systems will be able to achieve more stable communication and efficient frequency usage. For example, in the site where an Autonomous Mobile Robot (AMR) equipped with a combo device that supports multiple wireless systems of 5G and unlicensed frequency bands is introduced, stable communication is achievable by switching multiple wireless links and parallel transmission (Fig. 3). For example, (1) when an AMR moves while communicating on a radio system in an unlicensed frequency band, and the unlicensed frequency band is congested by other devices installed in the vicinity, the communication path is switched to 5G, and (2) when the AMR transmits and receives data related to control such as for moving and stopping, and video data from cameras mounted on AMR wirelessly, an autonomous control is conducted to transmit both data by appropriately switching between wireless systems in unlicensed frequency bands and 5G according to the congestion of the frequency band.

Furthermore, in the technical specifications Ver.2.0, a multi-hop communication function is added to relay the network with SRF Gateway, which is one of the elements consisting of the SRF wireless platform. This multi-hop communication enables wireless connections between SRF Gateways and connections between SRF Gateways via SRF Devices. This makes it possible to easily expand the coverage of stable wireless communication. In addition, by installing an SRF Gateway on a wired network, it is possible to support a mixed wired/wireless network and improve the flexibility of integrated control of multiple links, such as 5G and wired parallel transmission.

Fig. 3. 5G utilization example on SRF wireless platform

About Flexible Factory Partner Alliance (FFPA)

FFPA (Chairperson: Andreas Dengel, DFKI) is a non-profit organization to promote the formulation of standards for coordination control technology, ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities. Members are OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd, Siemens K.K, and Telcom Engineering Center.

https://www.ffp-a.org/index.html

Glossary

SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities. SRF (Smart Resource Flow) is a system engineering strategy of managing resources (e. g., human, facilities, equipment, materials, energy, and communications) using multilayer system analysis to achieve optimal performance.

November 09, 2021

November 09, 2021

Flexible Factory Partner Alliance

Andreas Dengel, FFFA Chairperson received "Order of the Rising Sun, Gold Rays with Neck Ribbon" of Japan.

Flexible Factory Partner Alliance proudly announces that Andreas Dengel, FFFA Chairperson awarded "Order of the Rising Sun, Gold Rays with Neck Ribbon" of Japan in the autumn of 2021.

This famous and high-ranking award of Japan was given to his remarkable contribution to the promotion of academic exchange and mutual understanding between Germany and Japan.

[ Prof. Dr. Prof. h.c. Andreas Dengel ]

- Professor, Technical University of Kaiserslautern

- Executive Director, German Research Center for Artificial Intelligence (DFKI)

- Chairperson, Flexible Factory Partner Alliance

October 14, 2021

October 14, 2021

Flexible Factory Partner Alliance

FFPA's Technical Specifications for the Industrial Wireless Standard are Now Publicly Available

- Pushing to connect various wireless equipment under total management in factories -

Flexible Factory Partner Alliance (FFPA, Chairperson Andreas Dengel) has opened the technical specifications, namely Smart Resource Flow (SRF) wireless platform*1 to the public on the web site.

The SRF wireless platform aims to ensure stable operation of various wireless systems co-located in factory sites, originally proposed by National Institute of Information and Communications Technology (NICT). FFPA completed the technical specifications in 2019 and the conformance test specifications in January, 2021. In order for many vendors to consider making their products compliant with the SRF wireless platform standard, FFPA has decided to open the technical specifications version 1.1 to the public. Increasing certified products facilitate realization of the scheme for visualization and total management of wireless systems with different standards, in different generations, and by different venders with stable operation ensuring coexistence and coordination.

The technical specifications describe definitions of functions for settings, control policies and monitoring of wireless equipment, and messages for an application interface, i.e., REST API. FFPA prepares the certification program scheduled to start in this year. In the program, controllers, gateways, devices (wireless terminals) and sensors are certified as standard-compliant-products for the SRF wireless platform.

FFPA is also developing the technical specifications version 2.0 extending functions to support 5G (5th generation mobile communication system) and wired- and wireless-integrated networks. FFPA continues promotion to introduce wireless technology to factory sites by spreading use of the SRF wireless platform.

[ Background ]

At factory sites, in order to address macro issues including automation, labor-saving and challenges of high-mix and low-volume production, there are increasing opportunities to control robots and automated carriers, and to provide inspection, analysis and work support using AI and IoT based on real-time information from workers and manufacturing equipment. Now we are in the new normal era, requiring new production process and management that enable remote monitoring and remote operation without workers sticking to the factory site. Under these circumstances, wireless communication has become indispensable in order to provide a means of communication for workers with mobile devices and automated carrier e.g., Automated Guided Vehicles (AGVs), and to emphasize configurability of manufacturing facilities.

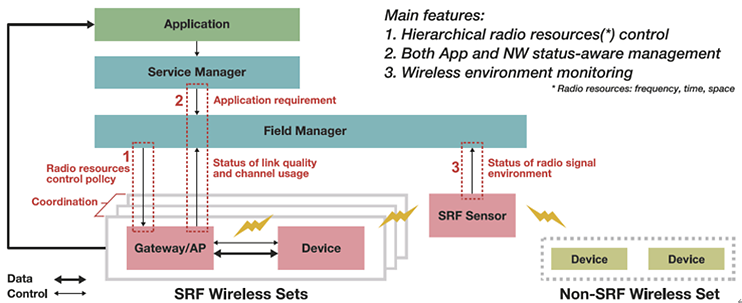

Several wireless systems with different standards, in different generations, and by different venders often coexist in the factory site. In such a case, coordination between the wireless systems may not occur, resulting in communication problems. In addition, the wireless system may not be able to perform stable communication due to factors such as layout changes, movement of surrounding objects, and interference from other wireless systems. As an activity to solve these problems, FFPA has been developing technical specifications of SRF wireless platform (Figure 1) which aims to ensure stable operation of various wireless systems co-located in factory sites.

FFPA completed the technical specifications version 1.0 of the SRF wireless platform in 2019 and the conformance test specifications in January, 2021 in order to tackle these issues with connecting wireless devices developed by different vendors, and to realize visualization and total management of wireless networks.

[ Publicly release of the technical specification ]

FFPA has released the technical specifications version 1.1 to the public on the web site, offering an opportunity for the vendors to consider to adopt the SRF wireless platform for their products. The technical specifications are downloadable for free from the FFPA web site (https://www.ffp-a.org/contact-spec-en/).

The released technical specifications provide reference architecture, functions, interfaces among the functions, messages, typical sequence diagrams and data frame of SRF wireless platform. Wireless components shown in Figure 2, namely the Field Manager (controller), SRF Gateway/AP, SRF Device, and SRF Sensor, make up system configuration. Definitions of functions for settings, control policies and monitoring of the wireless components, and messages for an application interface, REST API have also been described. The SRF wireless platform can provide wireless systems in different generations, with different standards, and by different venders with stable operation ensuring coexistence and coordination in factories sites.

To encourage wireless utilization further in factory sites, the technical specifications version 2.0 under development will provide functions to control 5G which can realize the coordination control between 5G and wireless technologies in unlicensed bands. Moreover, the extension of network topologies in the technical specifications will support wired- and wireless-integrated networks and are easily expandable coverage of wireless networks.

The certification program, which is scheduled to start in this year, uses a test tool and reference devices to certify that the product complies with the technical specifications of the SRF wireless platform. A logo in Figure 3 will be granted for the certified product. In order to access the conformance test specifications and to participate in the certification program, it is required to become an FFPA member. For detail information, please contact FFPA Secretariat (info@ffp-a.org).

[ Future Prospects ]

FFPA prepares certification program scheduled to start in 2021. FFPA continuously promotes the spread of the SRF wireless platform that enables visualization of various information on the factory site and total management of equipment connected to the network for the use of information and communications technology to improve productivity.

About Flexible Factory Partner Alliance (FFPA)

FFPA (Chairperson: Andreas Dengel, DFKI) is a non-profit organization to promote the formulation of standards for coordination control technology, ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities. Members are OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd, Siemens K.K, and Telcom Engineering Center.

https://www.ffp-a.org/index.html

Glossary

*1 SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities. SRF (Smart Resource Flow) is a system engineering strategy of managing resources (e. g., human, facilities, equipment, materials, energy, and communications) using multilayer system analysis to achieve optimal performance.

Figure 1. An image of operation of SRF Wireless Platform.

Figure 2. Configuration for coordination control of multiple wireless systems.

![]()

Figure 3. Logo of SRF wireless platform.

January 19, 2021

January 19, 2021

Flexible Factory Partner Alliance

FFPA Completes Conformance Test Specifications for SRF Wireless Platform to Stabilize Various Wireless Systems

- Providing total management for wireless networks connecting equipment in factories -

Flexible Factory Partner Alliance (FFPA, Chairperson Andreas Dengel) has created conformance test specifications for the technical standard, namely Smart Resource Flow (SRF) wireless platform*1 that is aiming for various wireless systems co-located in factory sites to operate stably. National Institute of Information and Communications Technology (NICT) has proposed the SRF wireless platform, which has been standardized by FFPA since September, 2019. The conformance test specifications define criteria and procedures, and thus, it is possible for vendors to confirm that their products comply with the SRF wireless platform technical specifications. This is a big step toward realization of visualization and total management of wireless networks in the factory site.

The SRF wireless platform technical specifications define functions and interfaces to connect among wireless systems in different generations, with different standards, and by different venders, and to ensure coexistence and coordination for stable operation. This time, the technical specifications have been also updated to Ver. 1.1 to support control parameters for Bluetooth/Bluetooth Low Energy (BLE) and Sub-GHz systems such as LoRaWAN in addition to Wireless LAN, and high-resolution spectrum monitoring.

[ Background ]

At factory sites, in order to address macro issues including automation, labor-saving and challenges of high-mix and low-volume production, there are increasing opportunities to control robots and automated carriers, and to provide inspection, analysis and work support using AI and IoT based on real-time information from workers and manufacturing equipment. Now we are in the new normal era, production process and management are shifting to those enable remote monitoring and remote operation without workers sticking to the factory site. Under these circumstances, wireless communication has become indispensable in order to provide a means of communication for workers with mobile devices and automated carrier e.g., Automated Guided Vehicles (AGVs), and to emphasize configurability of manufacturing facilities.

Several wireless systems in different generations, with different standards, and by different venders often coexist in the factory site. In such a case, coordination between the wireless systems may not occur, resulting in communication problems. In addition, the wireless system may not be able to perform stable communication due to factors such as layout changes, movement of surrounding objects, and interference from other wireless systems.

In September 2019, FFPA published the technical specifications Ver. 1.0 of the SRF wireless platform in order to tackle these issues with connecting wireless devices developed by different vendors, and easily to realize visualization and total management of wireless networks. Multiple wireless systems built on this platform will be able to operate together by mitigating interference with each other.

[ Achievements ]

FFPA has finalized the conformance test specifications for the SRF wireless platform. In the architecture of the SRF wireless platform, Field Manager (i.e., coordinator) manages and controls multiple wireless systems consisting of Gateways and Devices with coordination. The conformance test specifications describe criteria and procedures for the Gateways and Devices to communicate properly with Filed Manager. These test specifications make it possible to confirm that products by various vendors operate comply with the SRF wireless platform technical specifications.

Furthermore, the SRF wireless platform technical specifications have been updated to Ver. 1.1. In the technical specifications, control parameters for Bluetooth/Bluetooth Low Energy (BLE) and Sub-GHz systems such as LoRaWAN in addition to Wireless LAN, and high-resolution spectrum monitoring, have been added. By adopting this platform, it is possible to realize visualization and total management of networks consisting of a variety of wireless systems.

[ Future Prospects ]

FFPA is preparing certification program scheduled in 2021. It is also developing technical specifications Ver. 2.0 mainly to support 5G (5th generation mobile communication system). FFPA continuously promotes the spread of the SRF wireless platform that enables visualization of various information on the factory site and total management of equipment connected to the network for the use of information and communications technology to improve productivity.

About Flexible Factory Partner Alliance (FFPA)

FFPA (Chairperson: Andreas Dengel, DFKI) is a non-profit organization to promote the formulation of standards for coordination control technology, ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities. Members are OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd, Siemens K.K, and Telcom Engineering Center.

https://www.ffp-a.org/index.html

Glossary

*1 SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities. SRF (Smart Resource Flow) is a system engineering strategy of managing resources (e. g., human, facilities, equipment, materials, energy, and communications) using multilayer system analysis to achieve optimal performance.

Configuration for coordination control of multiple wireless systems.

April 9, 2020

5G Alliance for Connected Industries and Automation (5G-ACIA)

Flexible Factory Partner Alliance (FFPA)

April 09, 2020

5G-ACIA and FFPA sign MoU on Industrial Wireless Communications

- Driving Global Ecosystems for Industrial 5G -

The 5G Alliance for Connected Industries and Automation (5G-ACIA) and the Flexible Factory Partner Alliance (FFPA) have signed a Memorandum of Understanding (MoU) to cooperate over and build a successful global ecosystem for industrial wireless communications to improve automation, particularly regarding Industrial 5G. This new partnership aims to accelerate wireless utilization in smart manufacturing.

5G-ACIA and FFPA have already been exchanging information on new opportunities in the domain of industrial wireless communications for the past two years. As the market needs for 5G become more prominent in this area, both parties have decided to establish a closer relationship. The relevant items of activities on MoU are identification of topics for collaboration, e.g., joint development and analysis of use cases and requirements, joint marketing and promotional activities, and exchange of information and publications.

"We are excited to enter the next phase of collaboration with FFPA" said Dr. Andreas Mueller (Bosch), Chairman of 5G-ACIA. "Building upon the good and fruitful partnership we already had in the past, we look forward to further strengthen our ties and to jointly pave the way for the widespread adoption of wireless communication and in particular 5G in the manufacturing and process industries." For 5G-ACIA, the industrial powerhouse Japan is a key country, due to its many end users as well as its many OT and ICT companies. "Therefore, we look forward to gaining even more traction with Japanese stakeholders and to further expand our global footprint."

Dr. Kenichi Maruhashi (NEC), Representative Director of FFPA added, "We have been waiting for 5G to be available on the market. Our technical specifications of Smart Resource Flow (SRF) wireless platform have been developed for coordination control, mainly among unlicensed-band wireless communication systems, to ensure stable operation even in a factory environment. Until now, high-capacity, ultra-low-latency and licensed-band wireless technology, that is 5G, was a missing piece. Collaboration between 5G-ACIA and FFPA will manifest a vision for future factories with wireless-connectivity to enhance productivity."

About 5G-ACIA:

The 5G Alliance for Connected Industries and Automation (5G-ACIA) is the central global forum for shaping industrial 5G standards.

5G-ACIA members jointly prepare for the disruptive change that 5G will bring, promote a better understanding of industrial needs,

and gain insights into a highly attractive emerging market. 5G-ACIA provides a unique platform for OT and ICT companies, academia,

and all relevant stakeholders to influence 5G development and deployment, in line with industrial imperatives.

The currently more than 60 member organizations make the results of their work directly available to 3GPP,

the main standardization body for developing 5G. 5G-ACIA is a market representation partner of 3GPP and has the formal status of a working party of ZVEI

- German Electrical and Electronic Manufacturers' Association.

https://www.5g-acia.org

About Flexible Factory Partner Alliance:

Flexible Factory Partner Alliance (FFPA) is a non-profit organization to promote the formulation of standards for coordination control technology,

ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities.

FFPA standardizes and promotes SRF wireless platform which covers different wireless technologies.

5G connectivity will be added in the next version of the technical specifications.

https://www.ffp-a.org

The next 5G-ACIA Tokyo workshop is scheduled on September 17, 2020. Further information can be found here:

https://www.5g-acia.org/events/5g-acia-workshop-in-tokyo-japan/

Contact for the press:

Flexible Factory Partner Alliance

Hajime Koto

+81 42 327-7209

info@ffp-a.org

5G-ACIA

Sven Stern

+49 69 6302-404

SvenMorten.Stern@zvei.org

January 9, 2020

Flexible Factory Partner Alliance

January 9, 2020

Technical Specifications Available to Stabilize Various Wireless Communication Systems Co-located in Factory Sites

- FFPA starts to invite adopter members to access the specifications -

Flexible Factory Partner Alliance (FFPA, *1) provides the technical specifications that is aiming for various wireless systems co-located in factory sites to operate stably.

The specifications have been standardized based on Smart Resource Flow (SRF) wireless platform (*2) originally proposed by National Institute of Information and Communications Technology (NICT), making it easy to visualize and interactively manage various information on the manufacturing sites. The technical specifications define functions and interfaces to provide framework for coordination and coexistence of wireless systems with different standards, of different generations, and by different vendors coexisting in a same factory site.

FFPA has started to invite adopter members (*3) who can access the technical specifications. Please contact info@ffp-a.org for inquiries. FFPA is developing test specifications for preparation of certification program starting around in the middle of 2020.

*1 Flexible Factory Partner Alliance (FFPA)

FFPA (Chairperson: Andreas Dengel, DFKI) is a non-profit organization to promote the formulation of standards for coordination control technology,

ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities.

URL http://www.ffp-a.org/jp-index.html

*2 SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities.

SRF (Smart Resource Flow) is a system engineering strategy of managing resources

(e. g., human, facilities, equipment, materials, energy, and communications) using multilayer system analysis to achieve optimal performance.

*3 FFPA adopter members

FFPA adopter members have right to (a) access the technical specifications, (b) make products compliant with the technical specifications,

and (c) join certification program (to be planned).

September 24, 2019

September 24, 2019

Flexible Factory Partner Alliance

National Institute of Information and Communications Technology

FFPA Completes Technical Specifications to Stabilize Various Wireless Communication Systems Co-located in Factory Sites

- A progress toward visualization and integrated management of various information -

Flexible Factory Partner Alliance (FFPA, Chairperson Andreas Dengel) has created the technical specifications that is aiming for various wireless systems co-located in factory sites to operate stably. National Institute of Information and Communications Technology (NICT) has proposed Smart Resource Flow (SRF) wireless platform*1 which has been adopted as architecture for the specifications. By adopting this platform, stable wireless communication is realized, making it easy to visualize and interactively manage various information on the manufacturing sites.

The technical specifications define functions and interfaces to provide framework for coordination and coexistence of wireless systems with different standards, of different generations, and by different vendors coexisting in a same factory site.

An overview of the specifications will be presented at the FFPA seminar, "A vision of future factory sites created with the SRF wireless platform - Introduction of FFPA technical specifications Version1 -" held on October 31 in Tokyo.

[ Background ]

In the factory sites, usage of Information and Communications Technology (ICT) is increasing to enhance productivity by flexible operation releasing constrains of shortage of skilled workers and workstyle change nowadays. Especially for use of wireless commutations, voices from factory sites include:

·Need to monitor conditions of old machines by retrofit wireless sensors.

·Need to remotely monitor and control moving objects, e.g., human and automated guided vehicles (AGVs).

·Need to flexible change processes and layouts of factory sites without costly and time-consuming rewiring of cables.

Wireless communication is indispensable methods to cover these needs. More and more wireless systems have been becoming introduced to accompany manufacturing equipment for status monitoring, product inspection, process management, environment sensing, and machine control, and so on.

There are concerns such as communication instabilities that lead to impact on the current equipment due to interference among wireless systems in unlicensed spectrum where they operate independently and sometimes cannot meet requirements for communications due to degradation of wireless link quality. To address the issues on a technical approach, NICT has proposed the SRF wireless platform to define functions and interfaces among them. FFPA has established since July, 2017 to promote the SRF wireless platform into implementation for use in industries and to make an effort to create the specifications of wireless communications.

[ Achievements ]

FFPA has finalized the technical specifications defining functions and interfaces to pursue commercialization based on architecture of the SRF wireless platform proposed by NICT. The specifications enable wireless communication stabilities, and facilitate visualization and integrated management of various information on the manufacturing sites.

The technical specifications also provide framework for coordination and coexistence of wireless systems with different standards, of different generations, and by different vendors coexisting in the same factory site.

In the architecture of the SRF wireless platform, Field Manager (i.e. coordinator) manages and controls multiple wireless systems consisting of gateways and wireless terminals with coordination (global control).

The features are:

·Radio resources of frequency, time and space assigned to each system by setting control policy,

·Management with cognitive ways of both wireless communications and factory applications, and

·Monitoring wireless environment on the SRF wireless platform.

In addition, each system is allowed to have autonomous internal control based on the control policy to adapt to rapidly local change in wireless environment (local control).

An overview of the specifications will be presented at the FFPA seminar, "A vision of future factory sites created with SRF wireless platform - Introduction of FFPA technical specifications Version1 -" held on October 31 in Tokyo.

[ Future Prospects ]

FFPA is developing test specifications for preparation of certification program starting around in the middle of 2020. It also promotes the spread of the SRF wireless platform that enables visualization of various information on the factory site and integrated management of equipment connected to the network for the use of information and communications to improve productivity.

For further information on FFPA seminar (in Japanese)

https://www.ffp-a.org/news/jp-index.html#20190924a (in Japanese)

About Flexible Factory Partner Alliance (FFPA)

FFPA (Chairperson: Andreas Dengel, DFKI) is a non-profit organization to promote the formulation of standards for coordination control technology,

ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities.

Members are OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR),

National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd.,

Murata Machinery, Ltd, and Siemens K.K.

https://www.ffp-a.org/index.html

Glossary

*1 SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities.

SRF (Smart Resource Flow) is a system engineering strategy of managing resources (e. g., human, facilities, equipment,

materials, energy, and communications) using multilayer system analysis to achieve optimal performance.

Figure 1. Visualization and integrated management based on SRF wireless platform.

Figure 2. Configuration for coordination control of multiple wireless systems

June 6, 2019

Flexible Factory Partner Alliance

June 6, 2019

FFPA Received the "Info-Communications Promotion Month" Minister of Internal Affairs and Communications Award

The Flexible Factory Partner Alliance (FFPA) received the award from the Ministry of Internal Affairs and Communications for the Fiscal Year 2019 Info-Communications Promotion Month, for its contribution to promoting the establishment of factories with wireless connectivity and establishing international collaboration.

This award is awarded by the Ministry of Internal Affairs and Communications to individuals and organizations that are recognized as contributing to the development of the information and communication field or expected to have great potential for future creative activities in the digital content area.

FFPA continuously contributes to the standardization of technology to stabilize various wireless systems with coordination control, promotes the application of wireless communications in manufacturing factories that are expected to accelerate wireless-connected devices to increase productivity, and disseminates the standards.

The outline of the award is as follows.

[ Winner ]

Flexible Factory Partner Alliance

(Chairman: Andreas Dengel)

[ Achievements ]

Promoting the development of new wireless communication standards and international standardization efforts for stabilization of diverse wireless systems in manufacturing sites, and greatly contributing to establishment of international partnerships, such as deepening the relationship between the National Institute of Information and Communications Technology (NICT) and the German Research Center for Artificial Intelligence (DFKI).

[ Photos at the award ceremony ]

Awards for Central Memorial Ceremony of

Radio Day and Info-Communications Promotion Month

June 3, Imperial Hotel Tokyo

State Minister for MIC Yukari Sato (left),

Vice-Chair of FFPA Satoko Itaya (right)

FFPA members at the Ceremony

Director Amagai, Director Ikumo,

Vice-Chair Itaya, and Secretary-General Koto

(from left to right)

Info-Communications Promotion Month

Info-Communications Promotion Month has been established for the purpose of spreading and promoting information communication on the occasion of the system reform of the information communication in 1985. Various events concerning information communication are carried out throughout Japan during this period each year, for widely expanding the understanding and cooperation of Japan's residents about information communication, so to enrichen their quality of life.

About Flexible Factory Partner Alliance (FFPA)

FFPA is a non-profit organization promoting standards for coordination control technology, for ensuring stable communications in flexible manufacturing environments where various different wireless systems are being used together. The members of FFPA include OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), the National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd., and Siemens K.K.

April 1, 2019

Flexible Factory Partner Alliance

April 1, 2019

FFPA Releases Security Guidelines for Factory Network with Wireless Communications

The Flexible Factory Partner Alliance (FFPA) has released the Flexible Factory Security Guidelines for manufacturing environments using wireless networks. The Guidelines provide easy-to-understand and reliable guidelines for cyber security in factories. The Guidelines describe a basic framework for comprehensive security measures, with practical examples of assets to be protected, and their security threats and risks.

The Guidelines have been prepared for two main purposes

- to promote basic understanding of network security, and of procedures for secure management of devices, equipment, and systems wirelessly connected to factory networks, and

- to be a reference document that can help communication between manufacturing staff and security experts who are responsible for implementing security measures, such as security vendors, and security risk analysts.

Technical experts from security and IT vendors, FFRI, Inc., Kaspersky Labs Japan, NEC Corporation, and NTT Communications Corporation, have collaborated to develop these unique guidelines.

The Guidelines are available for free, and downloadable from https://www.ffp-a.org/document/index.html.

About Flexible Factory Partner Alliance (FFPA)

FFPA is a non-profit organization promoting standards for coordination control technology, for ensuring stable communications in flexible manufacturing environments where various different wireless systems are being used together. The members of FFPA include OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), the National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd., and Siemens K.K.

Oct 23, 2018

Flexible Factory Partner Alliance

National Institute of Information and Communications Technology

October 23, 2018

FFPA Unveils Draft Specifications to Stabilize Various Wireless Communication Systems Co-located in Manufacturing Sites

- Wireless communications energize flexible factory -

Flexible Factory Partner Alliance (FFPA), a non-profit organization formed by seven business corporations and the National Institute of Information and Communications Technology (NICT), unveils the draft specifications aiming to stabilize various types of wireless systems co-located in manufacturing sites. NICT proposed Smart Resource Flow (SRF) wireless platform*1 which has been adopted as the architecture for the specifications. FFPA has worked further to add necessary functions and interfaces for commercialization.

The draft specifications feature that Field Manager (i.e. Controller) manages multiple wireless systems with policy settings and monitoring, which is a framework for coordination and co-existence of wireless systems with different standards, of different generations and by different vendors in the same site of a factory. It promotes extensively use of ICT for improving productivity through visualization of information and total management in the factories.

The draft specifications will be presented at the FFPA's "Wireless Commutations Energize Flexible Factory" seminar, held on October 30 in Tokyo. A white paper will be open to public at the same time, which shows market needs and benefits to vendors, system integrators and operators, also describes technical aspects of the specifications.

[ Background ]

In the manufacturing sites, use of Information and Communications Technology (ICT) is increasing to enhance productivity under recent constrains like shortage of skilled workers and change of work style. The following needs are really raised.

·Monitor precise status of manufacturing equipment and results of inspection whether each process correctly completes for quality control.

·Ensure stable commutations among workers and production facilities including automated feeders and automated guided vehicles (AGVs).

·Enable flexible layout of machines and order of manufacturing processes to adapt to variable-type, variable-volume production and mass customization.

Wireless communication is one of the effective solution to cover these needs. More and more wireless systems have been introduced accompanying with manufacturing equipment for status monitoring, product inspection, process management, environment sensing, machine control, and so on.

Instabilities of communication are already emerging concerns. Due to interference among non-license required wireless systems operated independently, applications sometimes cannot keep enough bandwidth for communication quality. To address the issues technically, NICT has proposed SRF wireless platform that defines functions and information exchange protocols among them. FFPA established in July 2017 to promote SRF wireless platform into implementation for use in industries and to define the practical specifications for wireless communications in the manufacturing sites.

[ Achievements ]

FFPA has defined the draft specifications enhancing functions and interfaces for commercialization, based on the architecture of the SRF wireless platform proposed by NICT. In the draft specifications, Field Manager (i.e. controller) takes the role of managing and controlling multiple wireless systems consisting of gateways and wireless terminals (global control).

The features are:

·Radio resources of frequency, time and space assigned to each system by setting control policy,

·Management with cognitive ways of both wireless communications and factory applications,

·Monitoring wireless environment on the SRF wireless platform.

In addition, each system is allowed to have autonomous internal control based on the control policy to adapt to rapid local change in wireless environment (local control).

The framework adopted for the specifications enables to work with wireless systems and devices in different standards, of different generations, and by different vendors with existing wireless devices. For wider deployment, a part of the specifications refers IEEE 802.1*2 standards.

The specifications enable to provide:

·Reliability: No system interruption even in congested and dynamic wireless environments.

·Capacity: Supporting large numbers and large variety of wireless applications for improving quality and productivity.

·Stability and Maintainability: Management of data flow and wireless environments without IT experts.

The draft specifications will be presented in the FFPA seminar, "Wireless Commutations Energize Flexible Factory" held on October 30 in Tokyo. A white paper will be open to public at the same time, which shows market needs and benefits to vendors, system integrators and operators, also describes technical requirements of the specifications.

[ Future Prospects ]

FFPA continues to refine the specification in details and will finalize FFPA specifications (version 1.0) in the middle of 2019. Furthermore, by enabling visualization and total management of networks and the connected facilities in factories, FFPA promotes to utilization of ICT for improving productivity.

For further information on FFPA seminar

http://www.ffp-a.org/news/jp-index.html#20181003 (in Japanese)

About Flexible Factory Partner Alliance (FFPA)

FFPA is a non-profit organization to promote the standardization for coordination control technology, ensuring stable communications in an environment where various wireless systems coexist in manufacturing facilities. Members are OMRON Corporation, the Advanced Telecommunications Research Institute International (ATR), the National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, Sanritz Automation Co., Ltd., Murata Machinery, Ltd, and Siemens K.K. , at the end of September 30, 2018.

Glossary

*1 SRF Wireless Platform

System architecture to stabilize various wireless systems with connected facilities. SRF (Smart Resource Flow) is a concept to manage resources (e. g., human, facilities, equipment, materials, energy, and communications) using multilayer system analysis to achieve optimal performance by ensuring smooth flow of resources. Development of SRF wireless platform had been supported by the Ministry of Internal Affairs and Communications, Japan for the project entitled "R&D on Technologies to Densely and Efficiently Utilize Radio Resources of Unlicensed Bands in Dedicated Areas" since 2017.

*2 IEEE 802.1

The IEEE 802.1 Working Group is chartered to concern itself with and develop standards and recommended practices in the following areas: 802 Local Area Networking (LAN) /Metropolitan Area Networking (MAN) architecture, internetworking among 802 LANs, MANs and other wide area networks, 802 Security, 802 overall network management, and protocol layers above the Media Access Control & Logical Link Control layers. IEEE 802.1 interim meeting (January 14-18, 2019) will be in Hiroshima, Japan hosted by FFPA.

July 26, 2017

Flexible Factory Partner Alliance

OMRON Corporation

Advanced Telecommunications Research Institute International

Sanritz Automation Co., Ltd.

National Institute of Information and Communications Technology

NEC Corporation

Fujitsu Limited

Murata Machinery, Ltd.

July 26, 2017

Formation of Flexible Factory Partner Alliance to Accelerate Use of IoT in Factories

Promoting the spread of coordination control technology to ensure stable communications of various wireless systems

OMRON Corporation, Advanced Telecommunications Research Institute International (ATR), Sanritz Automation Co., Ltd., National Institute of Information and Communications Technology (NICT), NEC Corporation, Fujitsu Limited, and Murata Machinery, Ltd., today announced the formation of the Flexible Factory Partner Alliance (Chairperson: Professor Andreas Dengel of the German Research Center for Artificial Intelligence (DFKI)) to promote the formulation of standards for coordination control technology. This will work to ensure stable communications in an environment where various wireless systems coexist, as well as to promote their use and further accelerate the adoption of wireless systems in manufacturing facilities.

Through the initiatives of this alliance, the partners will seek to meet expectations for a new industrial revolution accompanying the spreading use of IoT in manufacturing facilities.

1. Background and Outlook

In response to fierce international competition resulting from increased globalization, as well as labor shortages and a reduced number of skilled workers due to falling birthrates and aging populations, utilizing ICT in manufacturing to improve productivity is seen as a critical issue. Given that ‘visualization’ in production equipment and production status is moving forward to improve productivity, and as product development cycles have shortened in recent years, there has been a demand for greater flexibility in the configuration of production facilities equipment and in modifying the production line construction. As a means of achieving greater flexibility, there are rising expectations for wireless communications as an important technology. In fact, there has been an increasing trend of manufacturing facilities deploying wireless communications on a trial basis, and then based on these trials, fully implementing such wireless systems.

At the same time, a major issue in wireless communications in factories where various wireless systems coexist is communication instability due to interference between wireless systems and the impact that has on equipment operation. There had previously been few efforts, however, to resolve this sort of wireless communication issue in manufacturing facilities.

To find solutions for the above issues, OMRON, ATR, Sanritz, NICT, NEC, Fujitsu, and Murata Machinery have been conducting trials of wireless communications and evaluating the wireless environment in factories. These companies and organizations have at academic conferences and other venues broadly proposed coordination control technology that would enable stability in communications. This would work by controlling independent wireless systems for each piece of equipment, with specific use cases in actual manufacturing facilities in mind.

Now these companies have come together to form the Flexible Factory Partner Alliance to promote the formulation of standards for coordination control technology. This will thereby ensure stable communications in an environment where various wireless systems coexist, as well as promote their use and further accelerate the adoption of wireless systems in manufacturing facilities. Professor Andreas Dengel of the German Research Center for Artificial Intelligence (DFKI) has been appointed the chairperson of this alliance.

Through the initiatives of this alliance, the partners will work to meet expectations for a new industrial revolution accompanying the spread of the use of IoT in manufacturing facilities.

2. Goals

The goal of this alliance is to contribute to the standardization of technology to stabilize various wireless systems with coordination control, promote the application of wireless communications in manufacturing factories that are expected to accelerate wireless-connected devices to increase productivity, and disseminate the standards.

3. Summary of Activities

The alliance will take the following actions to achieve the goals.

- Development of specifications relating to the technology to stabilize various wireless systems with coordination control

- Activities to standardize these specifications

- Activities to promote the application of wireless communications in manufacturing factories

- Activities necessary to achieve the goals of this alliance

4. Member information

OMRON Corporation (Headquarters: Shimogyo-ku Kyoto, President and CEO: Yoshihito Yamada)

Advanced Telecommunications Research Institute International (Headquarters: Souraku Kyoto, President: Toru Asami)

Sanritz Automation Co., Ltd. (Headquarters: Machida Tokyo, Managing director: Kazuya Suzuki)

National Institute of Information and Communications Technology (Headquarters: Koganei Tokyo, President: Hideyuki Tokuda)

NEC Corporation (Headquarters: Minato-ku Tokyo, President and CEO: Takashi Niino)

Fujitsu Limited (Headquarters: Minato-ku Tokyo, Representative Director & President: Tatsuya Tanaka)

Murata Machinery, Ltd. (Headquarters: Fushimi-ku Kyoto, President & CEO: Daisuke Murata)

Related Links

Flexible Factory Partner Alliance website: http://www.ffp-a.org/